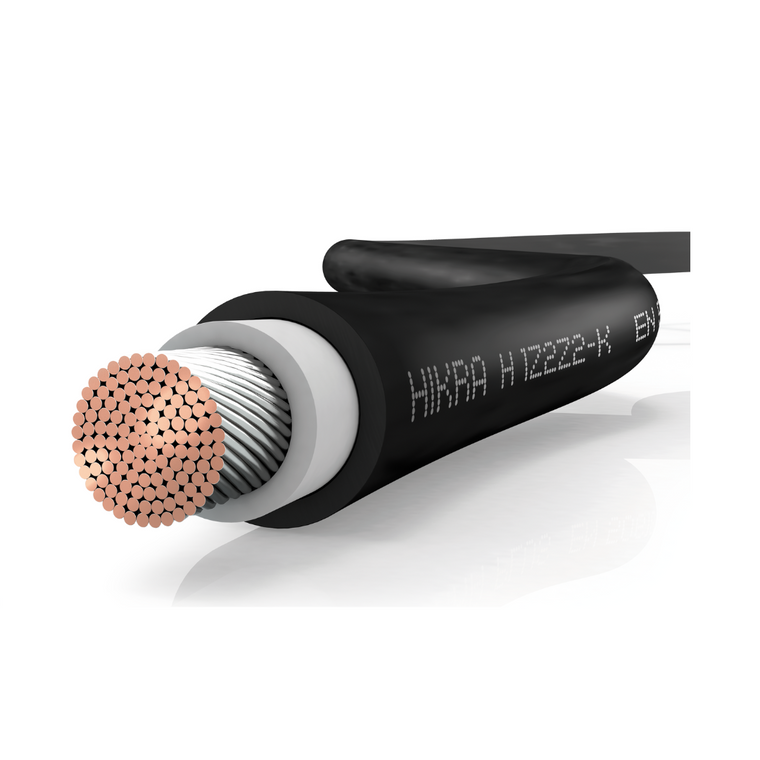

HIS HIKRA® SOL Black 6mm Cable

HISContact us for pricing

Log in for pricing

HIKRA® SOL EN50618 (H1Z2Z2-K) IEC62930 (IEC 131) TÜV 2 PfG 2750 (PV 1500-WR)

Features:

- Higher water resistance and increased mechanical stability

- UV-stable and high resistance to external influences

- Additionally certified for floating PV according to TÜV 2 Pfg 2750 (PV 1500-WR)

- 25 years expected service life

- Continuous meter marking

Datasheet :

|

Construction |

|

|

Strand construction |

Tin-plated copper strand (electrolytic copper), fine wire acc. IEC 60228 Class 5 |

|

Insulation |

Electron-beam cross-linked Polyolefin; Shore hardness D 32 |

|

Outer Sheath |

Electron-beam cross-linked special compound XLPO; Shore hardness D 36 |

|

Colour |

Sheath: black, red; Insulation: clear – naturally colored |

|

Making |

HIKRA SOL1500V H1Z2Z2-K IEC62930 1x6,0 mm² R 50408873 CE with meter marking |

|

Standards |

EN50618 (H1Z2Z2-K) TÜV R50363076; IEC62930 131 TÜV 50408873 |

|

Technical characteristics |

|

|

Nominal voltage |

1,5kV DC and 1,0kV AC |

|

Maximum permitted operating voltage: |

1,8kV DC (2,0 kV DC internal examination) |

|

Voltage test on complete cable |

6,5kV AC / 15kV DC (5 minutes water bath, 20±5 °C) |

|

Current carrying capacity |

See document „Current rating – HIKRA® Solar Cable“ October 2020 |

|

Short-circuit-temperature |

250 °C/5s |

|

Material properties |

|

|

UV stability |

Tensile strength and ultimate-elongation after 720 h (360 cycles) ≥ 70 % of initial values; EN 50289-4-17 acc. Method A; EN ISO 4892-1 (2000) and EN ISO 4892-2 (2006) |

|

Ozone resistance |

72h, relative humidity 55±5 %, Temperature 40±2 °C (EN 50396 Method B; Ozone concentration (200±50)x10-6 ) |

|

Insulation resistance |

Insulation resistance in water bath, each 2h at +90 °C and 2h at 20 °C (Limit values acc. EN 50618 Table 1) |

|

DC direct voltage test |

Water bath, at +85 °C +-5 °C, 240h, test voltage 1.8kV DC |

|

Advanced DC dc voltage test |

Water bath, at +85 °C +-5 °C, 240h, test voltage 3.6kV DC (Floating PV TÜV 2 Pfg 2750) |

|

Capacity measurement water storage |

14 days water storage at +90+-5 °C; capacitance measurement after 1 day. After 14 days capacity measurement max. 10 %, resp. after 7 days 4 % higher than compared to capacity measurement after day 1 (Floating PV TÜV 2 Pfg 2750). |

|

Dynamic penetration test |

Spring-steel-needle through insulation or sheath (EN50618 Annex D) |

|

Direct burial |

Long-term water immersion at 90 °C, duration 12 weeks; Insulation resistance ≥ 3GΩ (internal examination acc. UL44 cl. 5.4 & UL2556 6.4.4.2.1 |

|

Crushing- and impact-resistance |

Impact-Resistance UL 854.23 and Crushing-Resistance UL 854.24 (internal examination) |

|

Sheath resistance against acid and alkaline |

168h at 23 °C in N-Oxal acid and N-Sodium hydroxide (EN 60811-404); ammoniac-resistant |

|

Behavior in case of fire |

Flame-retardant acc. EN 60332-1-2 Annex A, low smoke emission (EN 61034,-2) |

|

CPR-Performance |

Dca; burning behavior acc. EN 50575:2014 |

|

Halogen-free |

EN 50525-1, Annex B |

|

Cold impact test |

EN 60811-506, EN 50618 Annex C.1 at -40 °C |

|

Cold elongation test |

Max. 30% elongation at -40±2 °C, 16h (EN 60811-505) |

|

Damp heat test |

Duration 1000h at 90 °C and min. 85 % relative humidity (EN 60068-2-78) |

|

Minimum bending radius flexible / fixed |

10x cable diameter | 4x cable diameter |

|

Temperature Range |

|

|

Temperature |

Ambient temperature: -40 °C to +90 °C; Maximum conductor temperature: +120 °C |

|

Maximum storage temperature |

+40 °C |

|

Minimum temperature for installation |

-25 °C |

|

Order No. |

Cross-section mm² |

Construction n x max. - Ø (mm) |

Max. resistance (Ω/km) |

External diameter (+/- 0,2 mm) |

Copper index kg/km |

Approx. Weight kg/km |

|

|

Black |

Red stripes |

||||||

|

739065 |

739066 |

1 x 1.5 |

29 x 0.25 |

13.7 |

4.6 |

14.0 |

32.0 |

|

738609 |

738610 |

1 x 2.5 |

47 x 0.25 |

8.21 |

5.0 |

24.0 |

41.0 |

|

738613 |

738614 |

1 x 4.0 |

52 x 0.3 |

5.09 |

5.4 |

38.4 |

54.0 |

|

738615 |

738616 |

1 x 6.0 |

78 x 0.3 |

3.39 |

6.0 |

57.6 |

73.0 |

|

738617 |

738618 |

1 x 10.0 |

77 x 0.4 |

1.95 |

7.2 |

96.0 |

120.0 |

|

738619 |

- |

1 x 16.0 |

126 x 0.4 |

1.24 |

8.7 |

153.6 |

189.0 |

|

739061 |

- |

1 x 25.0 |

190 x 0.4 |

0.795 |

10.4 |

240.0 |

277.0 |